A Day in the Life of an Apprentice Slatemason

9th August 2022

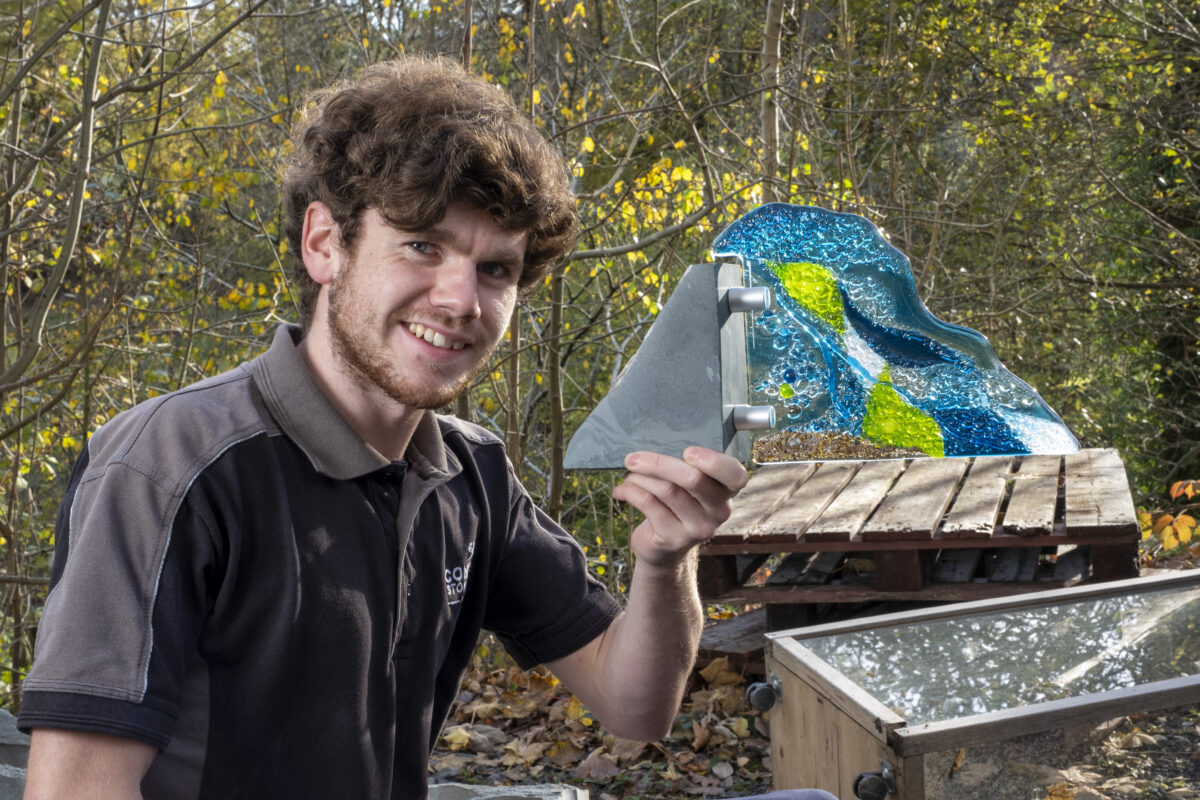

Slate has been mined and quarried in Cumbria for hundreds of years, and QEST Howdens Apprentice Liam Cartmel-Walker is a fourth-generation member of a slate-working family. He works at Coniston Stonecraft, the last slate manufacturers in the South Lakes, producing a range of household and kitchen products. Here he tells us more about his apprenticeship.

Why did you chose an apprenticeship?

Opportunities for lads like me are limited in our part of the UK, it’s either an apprenticeship in the shipyards at Barrow, hospitality, building submarines or BNFL at Sellafield. I am an outdoorsy type who likes to do stuff with my hands and all my family (my great-grandfather, grandfather and father) had worked for the Burlington quarries, so when I saw the advert for Coniston Stonecraft, it seemed to be my destiny.

The apprenticeship suits me because I can learn on the job and I’m being taught every day by very experienced slatemasons. Andy and George are great mentors and have about 45 years’ experience between them, so there’s nothing they can’t do with slate.

I spend one day a week at Furness College with the submarine makers (I’m the only slatemason apprentice in England so I have to join their engineering cohort) and I try to learn as much as possible so that I can progress as soon as I can – being a slatemason is not easy to learn but it is very rewarding.

What does your typical day look like?

There’s no such thing as a typical day, but there are rhythms to the day. I’ll get in at 8am and set the CNC going with the help of fellow apprentice Ciaran. Then I’ll look at my ‘clip‘ to see what the business needs before putting on the appropriate clothing – gloves, breathing filter, wellies and apron if I’m using any power tools that are cooled by water – we use water from the beck that runs outside our workshop rather than oil). Then I just crack on cutting, polishing and selecting the right slate for the job, measuring it twice and cutting it once. The day shoots by swiftly and it is enjoyable getting stuff done and finished and crossing it off my clip. We stop for regular breaks and if it’s not raining we all sit outside and chat – the banter is brilliant.

Tell us about your workplace and your team set-up

We work in old Victorian copper ore sorting sheds that were the end of the Coniston to Barrow railway line. They are on the Coniston Old Man mountain, so we get a lot of walkers dropping in to our shed and shop. We are just a small team – Andy, George and me are in the workshops, Laura and Ciaran do the admin, waxing and packaging, and Brendan is out delivering or dealing with customers a lot.

Andy and George keep me right and show me how to do everything properly and correct my mistakes, while Laura and Ciaran are a great help on the digital side of the business. We all just muck in to get the job done.

What do you like best about your about your job?

I like the feeling of making something beautiful, and find it very satisfying. I also like working with my hands in the Lake District – it’s just beautiful.

What is the biggest challenge you’ve faced during your apprenticeship, and your greatest achievement?

Being a good slatemason is not easy, but I have great mentors in Andy and George. My biggest challenge has been getting the formal education to validate my apprenticeship. At College the closest thing to slatemasonry is engineering, so the classes are full of submarine builders working in metal. However the course is good for CNC, health and safety and workshop practice, and I get a formal qualification at the end of it.

My greatest achievement, apart from my QEST award, has been making pieces that I can be really proud of, and that our customers appreciate. As I progress this gets easier – last week I made some absolutely beautiful pastry boards out of silver grey slate from the Old Bandy Crag Quarry (now defunct) and everyone said they were fantastic. I made 25 of them and they sold out before the end of the week.